NVIDIA Shield Stand

January 2021

Project Overview |

Developed Skills |

||

|

|

|

|

Objective

This project is a consulting job through UBC Rapid, where the client contacted us asking for us to design and print a stand for their NVIDIA Shield Pro.

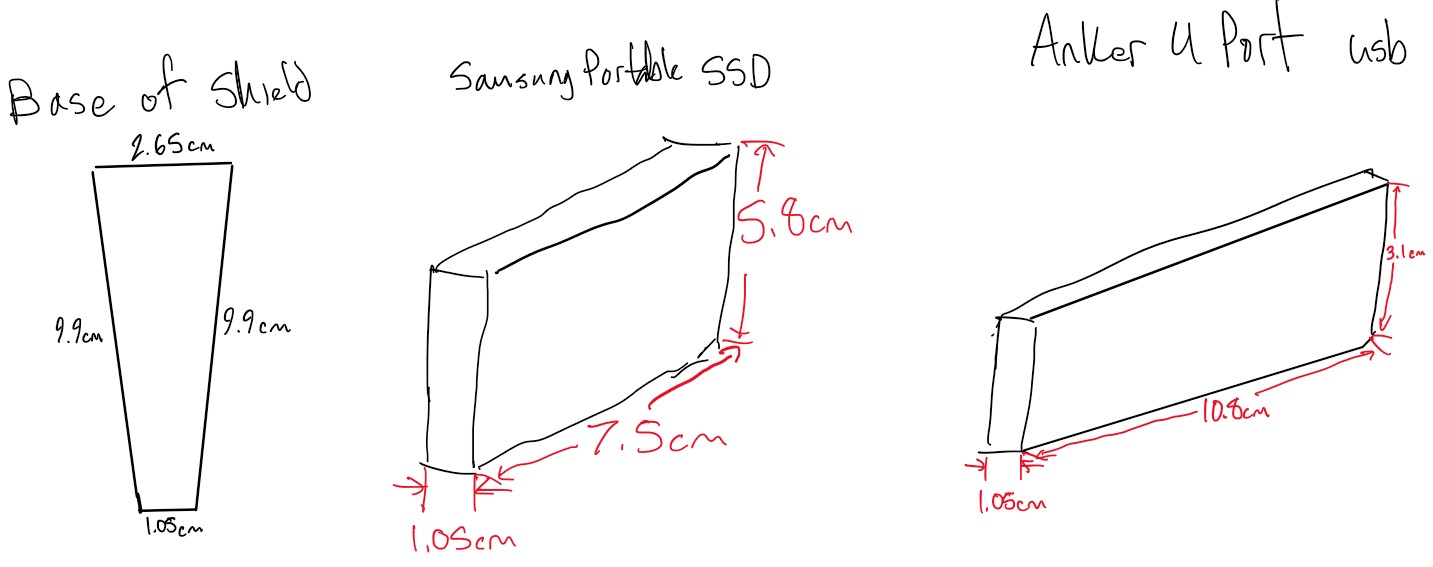

Client's provided dimensions sketched out

Contact with Client and Sketches

First, I read the client's job request, along with their provided dimension, and came up with any questions or clarifications I needed before returning an email.

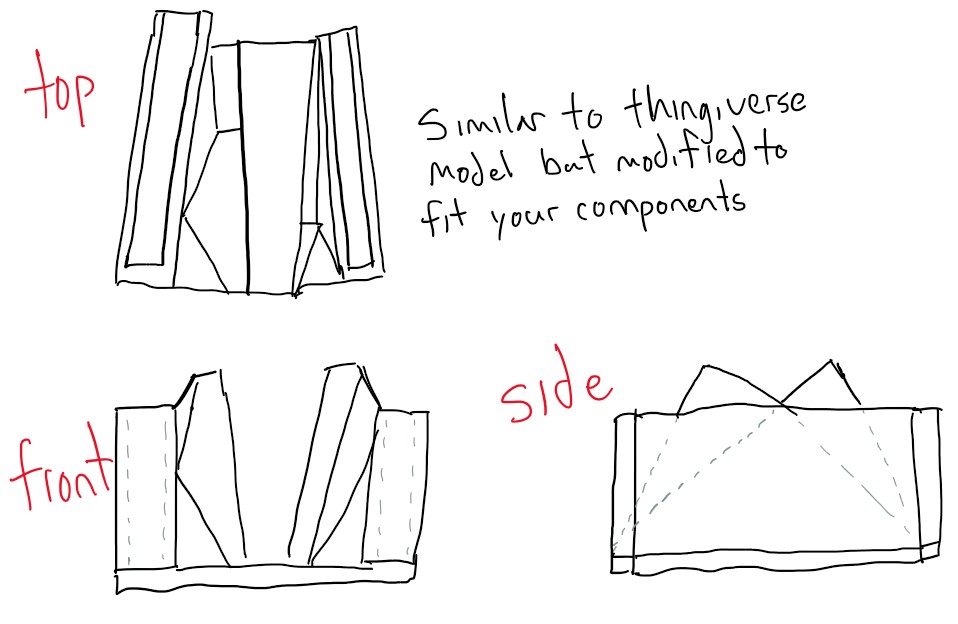

After emailing the client and hearing back from them, I prepared a few sketches of designs to show the client and ask them for feedback.

After the client chose their preferred design, I met with them to take my own measurements of their parts so I could guarantee a proper fit.

First concept sketch

Second concept sketch

My dimensions of parts

Preparing Models

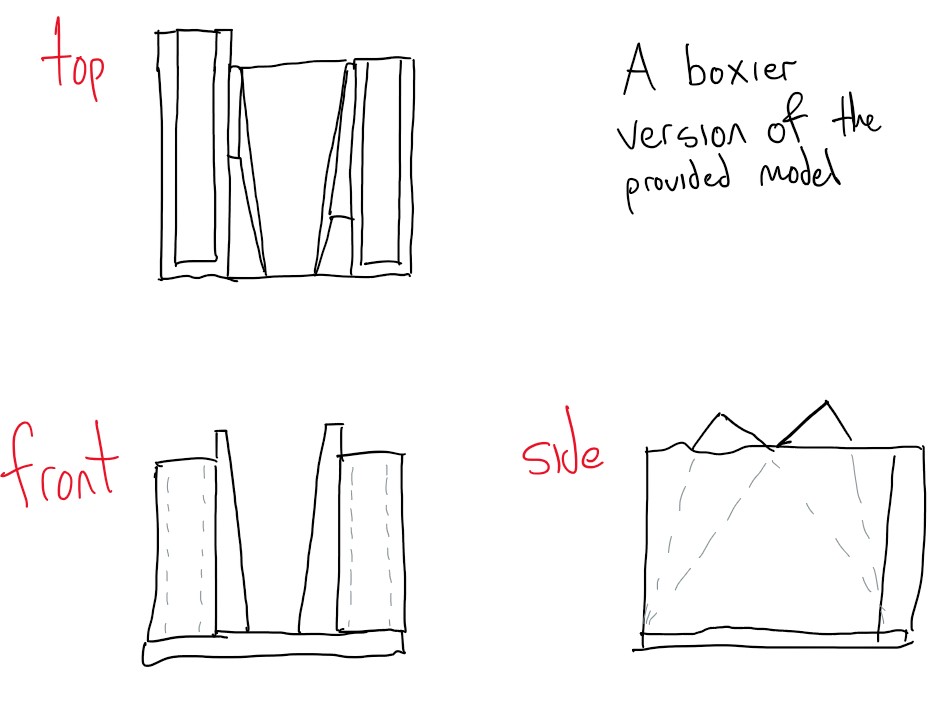

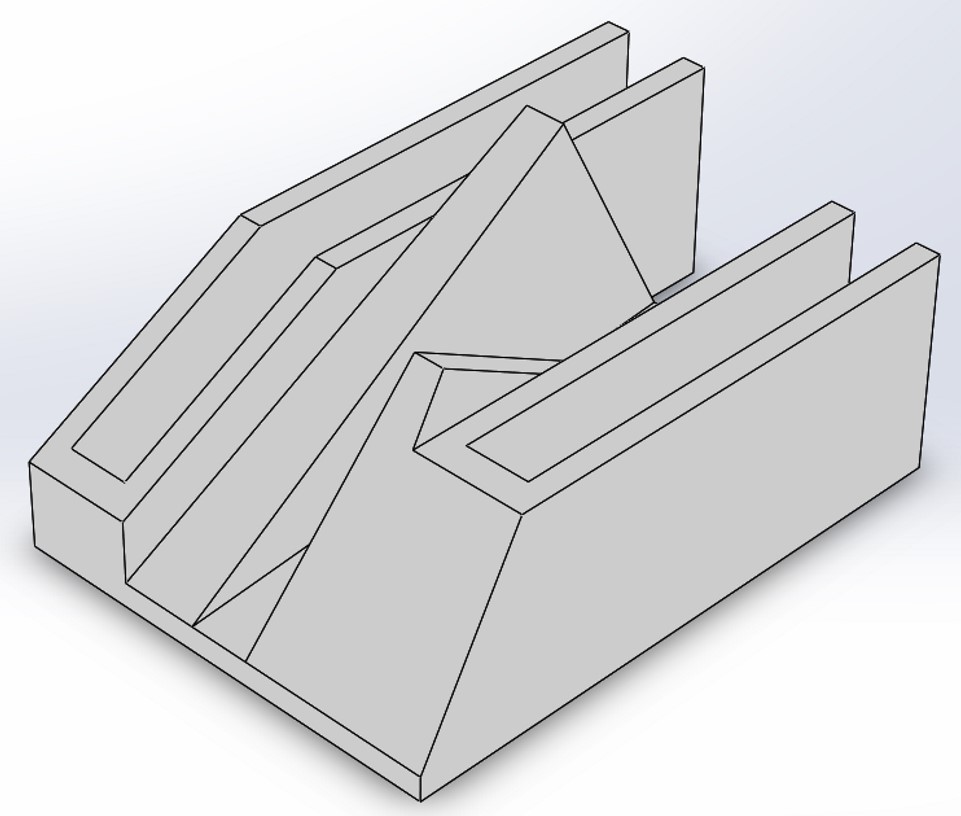

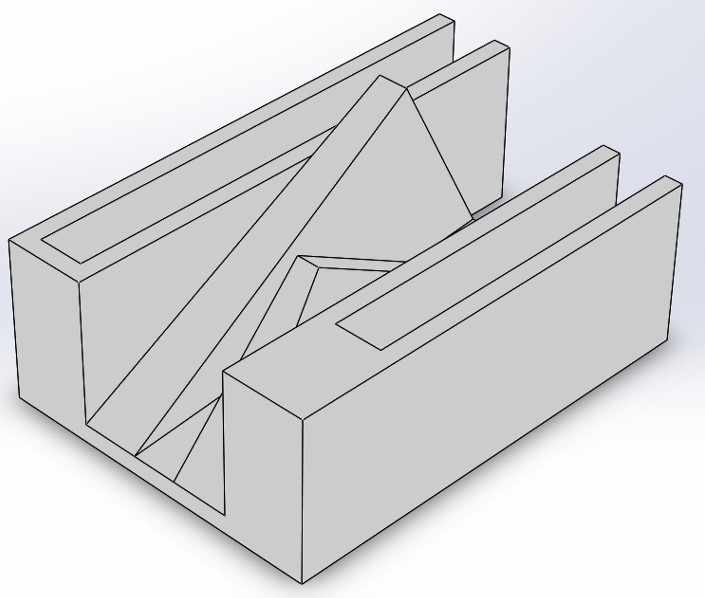

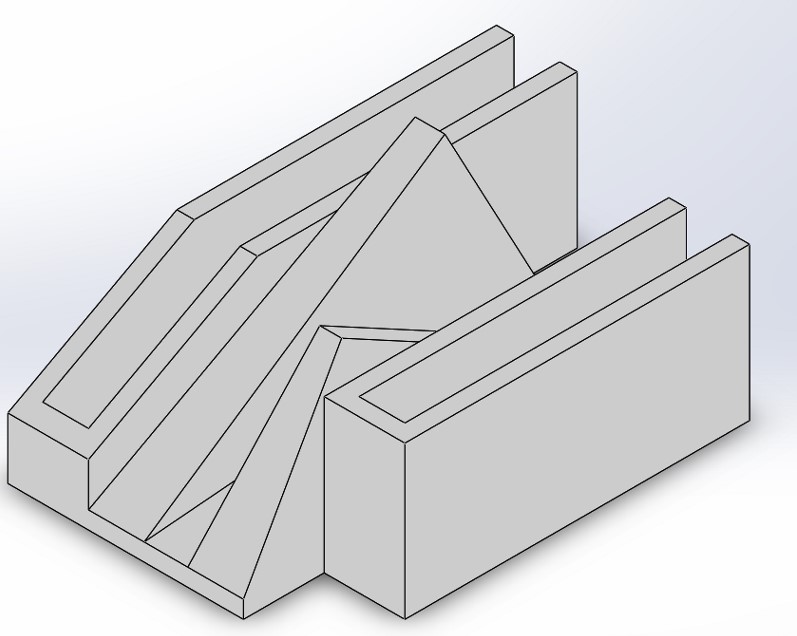

Once the client had chosen their preferred concept and I had taken the necessary measurements, I began modelling the part in SolidWorks.

I prepared three slightly different versions to the client for feedback on which version they liked more.

First concept model

Second concept model

Third concept model

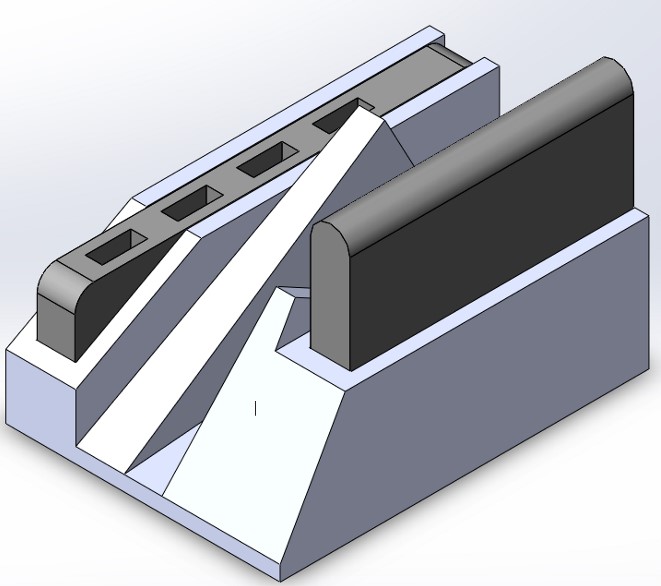

Model with parts fit inside

Testing Part Fit in SolidWorks

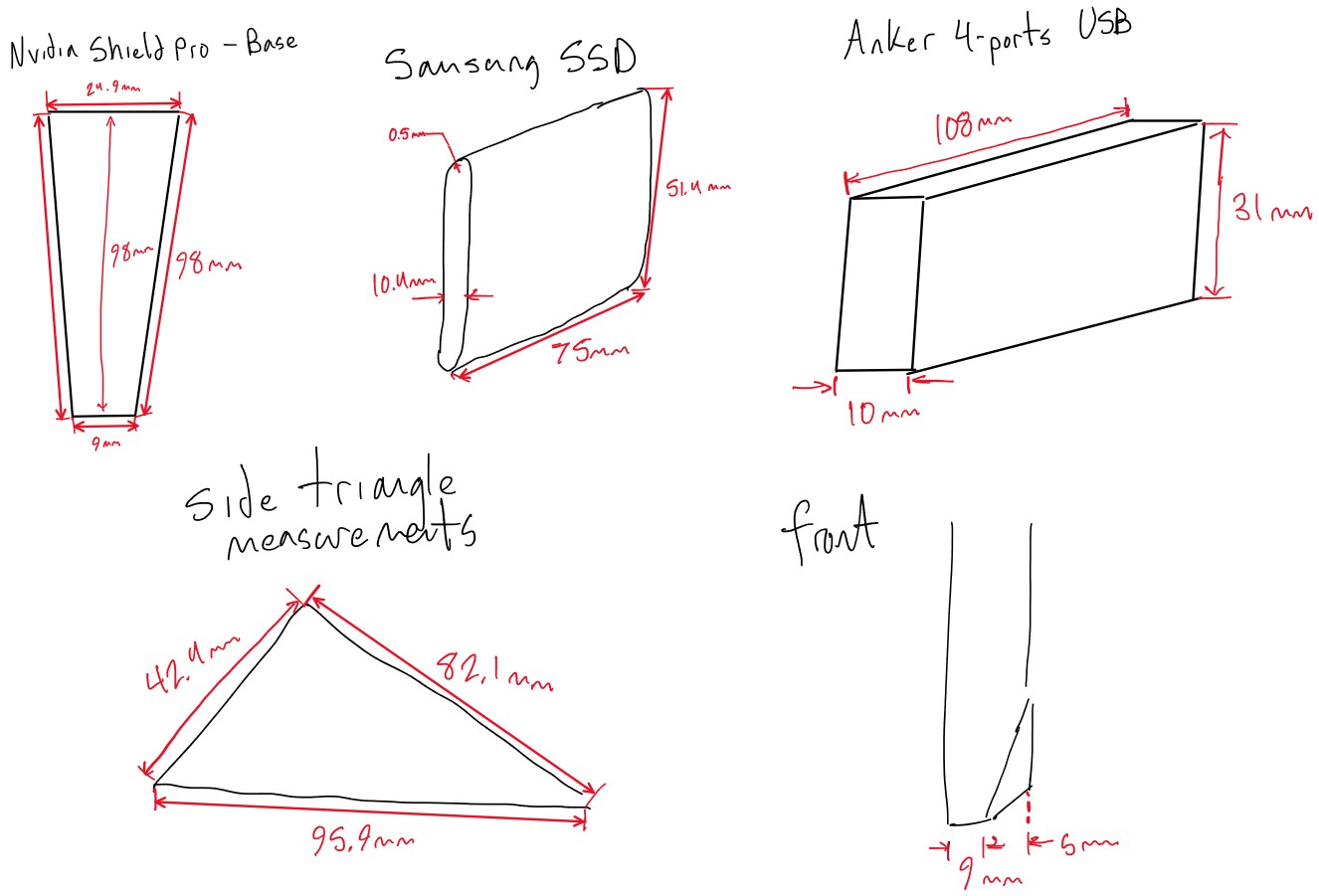

The client preferred the first concept model, so I made some basic models for the parts that will be placed inside to test their fit.

Using these fitted parts, I modified the model wherever necessary to include 3D printing tolerances until I was comfortable that it would work properly.

After completing the finishing touches, I exported the model as an .STL, brought it into Cura to slice it, and printed it out.

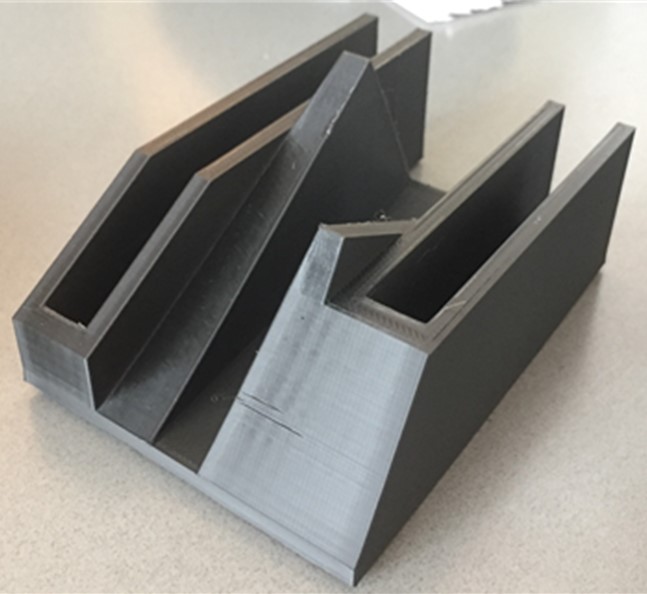

Final print

After printing out the part, I delivered it to the client so I could check the final fit to see if it was satisfactory.

The print ended up warping slightly on the bottom due to poor attachment to the print bed, but the client said this would not impact its use.

The client told me they were extremely satisfied with both the quality of the print and their service and they would recommend people to use our service.

Printed model

Final print with parts fit inside

Final Remarks

The regular communication with the client to gauge their feedback on the process ensured a satisfactory product would be delivered.

Taking my own measurements was a good idea, as a few crucial dimensions were missing with the client's initial set of measurements.

The client told me they were very satisfied with the service and unprompted, they told me they would recommend the service.