Bearing Staking Plan

October 2021

Project Overview |

Developed Skills |

||

|

|

|

|

Objective

This project was a task assigned to me at UBC Solar by the vehicle mechanics team lead. My task was to research the feasibility of using bearing staking to press spherical bearings into aluminum A-arms.

Staking tools

Bearing Staking

I used the New Hampshire Ball Bearings website to research the background of bearing staking, and to find the tables and figures outlining required forces.

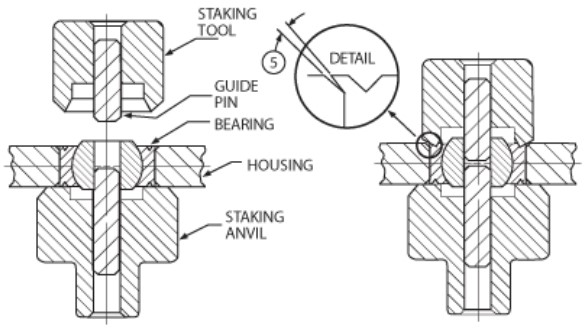

Bearing Staking Process

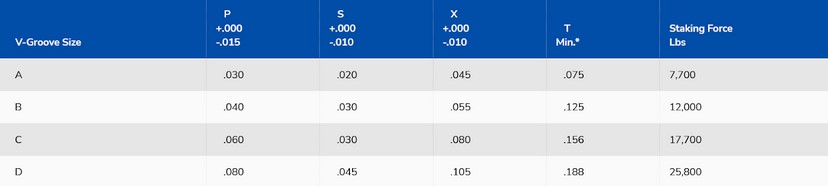

I found out the V-groove type of our existing bearings (type A) and I know the outer diameter of the bearing race (0.906").

From this I calculated the required staking force of 6976.2 lbs.

Drawing of staking process

V-groove size and force data from NHBB

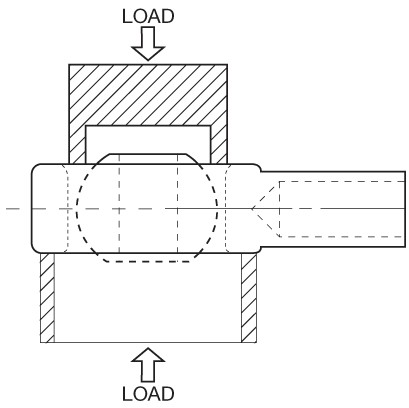

Thrust load test setup

Thrust Load Test Procedure

I researched the test procedure for the thrust load of staked bearings.

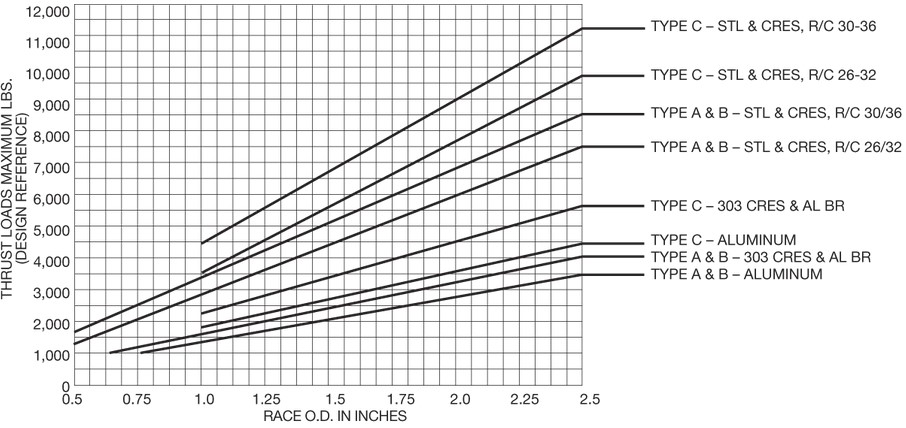

Using the figure below, I calculated our theoretical allowable load as ~1250 lbs.

Thrust load maximum for given O.D. and material

Contacting the Machine Shop

Since our required staking force was ~7kips, we needed access to a large hydraulic press.

Being certified to use UBC's MECH machine shop, we contacted them first to ask if they had a press and if they had any helpful information for us.

They told us we could book to use the press, however we would need our own staking tools.

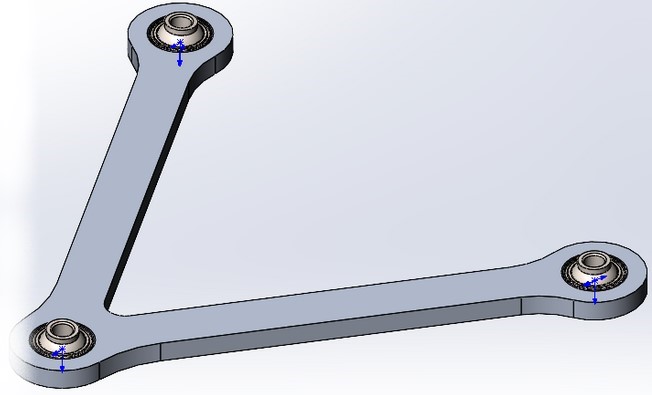

Aluminum A-arm to be bearing staked

Final Remarks

Unfortunately, the bearing staking tools were outside of the team's budget, so we have put this project on the shelf for now for when we can afford the tools (or a tooling company sponsors us).