Bearing Housing

October 2018

Project Overview |

Developed Skills |

||

|

|

|

|

Objective

This project was assigned to me by my team lead in the powertrain subteam of UBC Supermileage. I was tasked with redesigning a bearing housing and reducing its weight without comprimising the strength of the part.

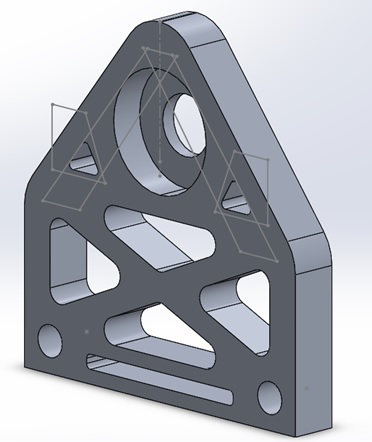

The original bearing housing

The Original Housing

With my task clear and the loading conditions known, I set out to measure the locations of the holes on the old housing and to record its mass so I wouuld have a baseline.

The original model was not very fully defined, having sketch lines protruding haphazardly throughout.

The existing bearing housing is cut out of Aluminum 6061 and has a mass of 153.69 grams.

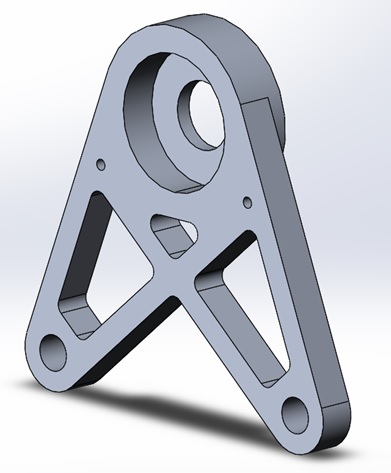

The New Housing

Taking the hole measurements I took from the original housing, I designed a new one in SolidWorks.

As can be seen from the picture on the right, the housing is much smaller and takes less material to produce.

The mass was cut down to 77.97 grams, a reduction of 50%! A significant improvement from the last design, to maximize mileage, every gram counts.

The new bearing housing

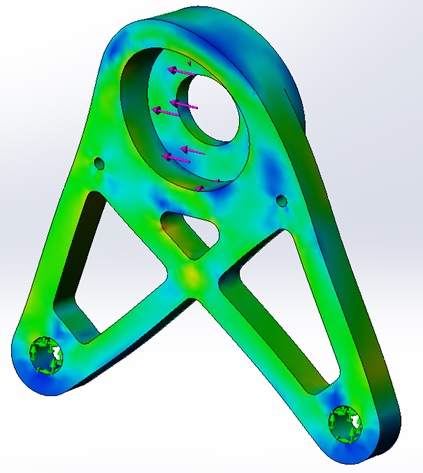

FEA simulation on the new housing

Bearing Housing Stress Test

Before an engineering drawing is created and the part can be machined, the part must pass a safety factor of 5. So a stress test is conducted in SolidWorks using the expected maximum load.

Through stress testing, the part passed the required safety factor of 5.

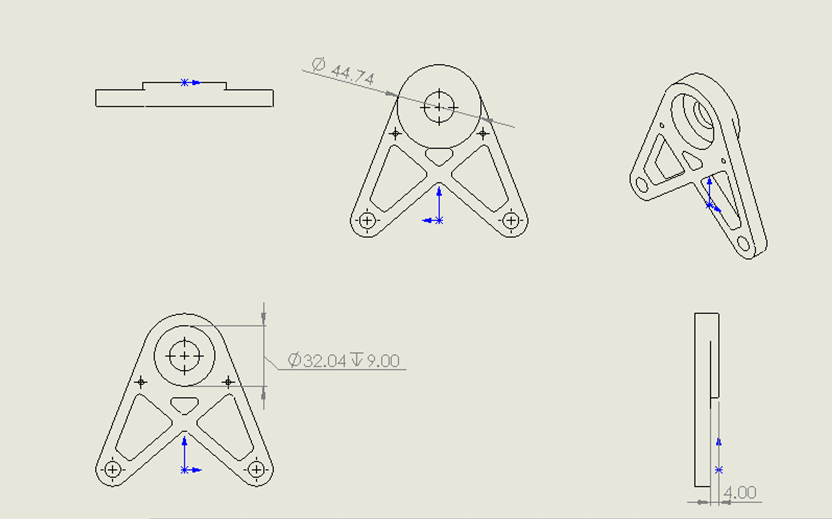

Draft for Machining

Using the built-in drafting tools in SolidWorks, I drafted and properly dimensioned the part, making sure to avoid any extraneous measurements.

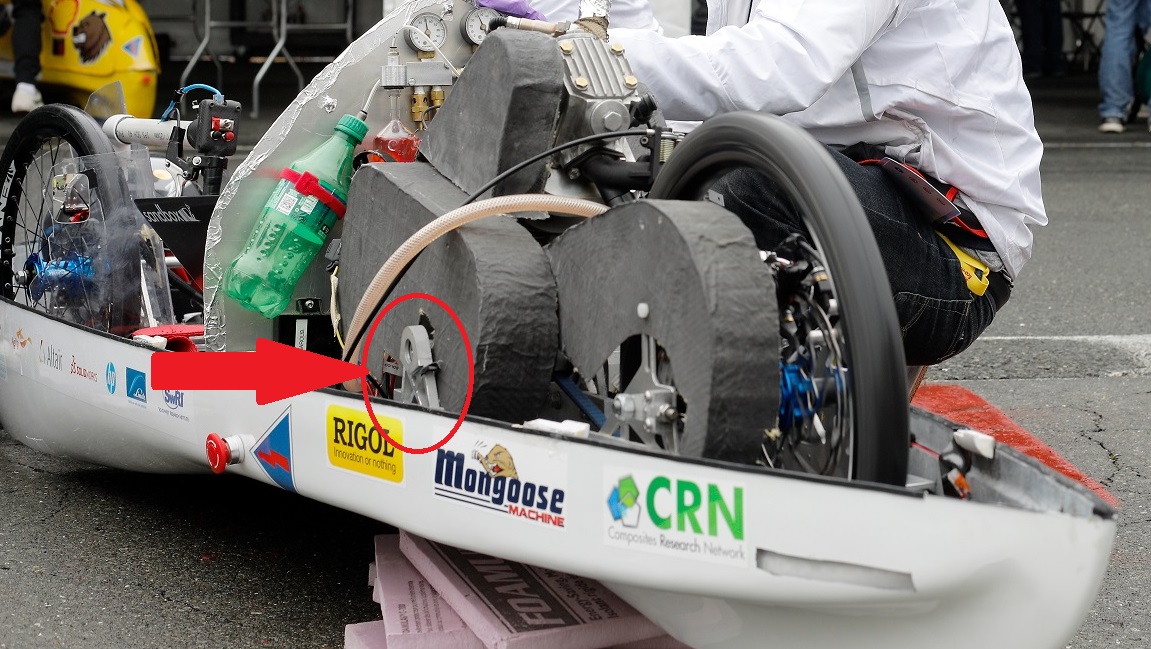

With the produced drawings, the part was properly machined and fitted to the prototype vehicle.

Drawing of housing

Prototype car at competition with housing

Final Remarks

Since I created this part in my first year of studying engineering, now that I am in my third year, I would have done a few things differently.

I have a greater understanding of stress concentrations and machnining, so I would have added fillets to any sharp edges in the part and I would have machined it myself.